Building Bridges between Reality and Data in Azure Digital Twin: A Comprehensive Guide

Digital twin is a virtual representation of a physical object or system. It enables us to simulate and monitor its real-world counterpart in a digital environment, offering valuable insights and analytics. The fundamental purpose of digital twins is to provide valuable insights, enhance decision-making, and optimize performance by simulating and monitoring the behaviour of their physical counterparts within a digital environment.

Why Digital twin in azure?

Azure Digital Twin is a groundbreaking platform developed by Microsoft that enables the creation and management of digital replicas of physical objects. This platform holds immense significance as it serves as a bridge between the physical and digital worlds. By providing a virtual representation of real-world entities, Azure Digital Twin facilitates simulation, monitoring, and analysis in a digital environment.

One of the key features of Azure Digital Twin is its ability to ingest real-time data from IoT Hub, allowing seamless integration with various Internet of Things (IoT) devices and sensors. This integration empowers businesses and industries to monitor and analyse the performance of their physical assets in real-time.

Moreover, Azure Digital Twin goes beyond simple representation. It incorporates advanced technologies such as machine learning and reasoning to enhance decision-making processes. The platform not only mirrors the current state of physical entities but also predicts and models their behaviour based on the collected data. This predictive capability is particularly valuable for implementing preventive maintenance strategies and optimizing operational efficiency.

In essence, Azure Digital Twin is a powerful tool that brings the benefits of the digital realm to the physical world. It opens up new possibilities for industries ranging from manufacturing and healthcare to smart cities, revolutionizing the way we understand, manage, and interact with the physical environment. As businesses increasingly embrace digital transformation, Azure Digital Twin stands out as a key enabler, offering a robust foundation for the seamless integration of the physical and digital landscapes.

Setting up Digital twin in Azure

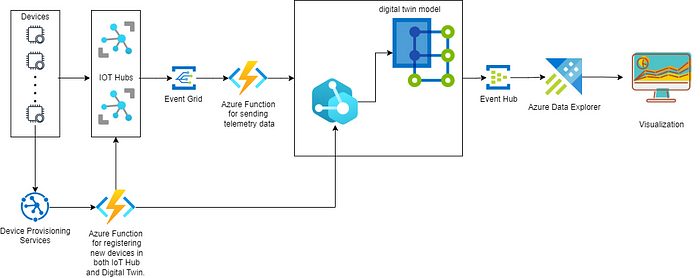

fig1:Architecture of Digital Twin Tech Demonstrator

The architecture is built upon a digital twin solution. Here, we have not only utilized Azure Digital Twin but have also integrated multiple other Azure services into our solution. We are creating a digital twin for a compressor that will send telemetry data to the IoT Hub. The IoT Hub contains a device with a unique device ID. New devices will only be created using Azure Device Provisioning. These provisions are achieved by utilizing digital certificates, triggering the Azure Device Allocation function, which creates the device in the respective IoT Hub. In Azure Digital Twin, we created a model for each device and its components. Subsequently, we created a twin and established relationships between these twins. These twins are updated whenever the Azure function is triggered.

Another Azure function is employed to facilitate communication between Azure Digital Twin (ADT) and IoT Hub. It sends telemetry data to ADT, updating the values in real-time. The data is then sent to Event Hub, which, in turn, forwards it to Azure Explorer. Visualization, analytics, and predictions are performed using the data contained in Azure Data Explorer.

A walkthrough for creating digital twin model for compressor

To begin, we must create an Azure Digital Twin in the Azure portal. Subsequently, we should access the Digital Twin through the Azure Digital Twin Explorer. The first step in establishing the Digital Twin involves creating a model using the Digital Twin Definition Language (DTDL).

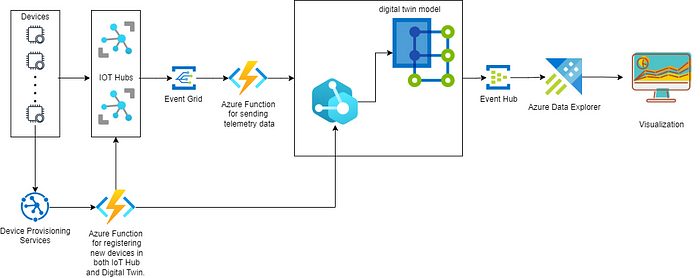

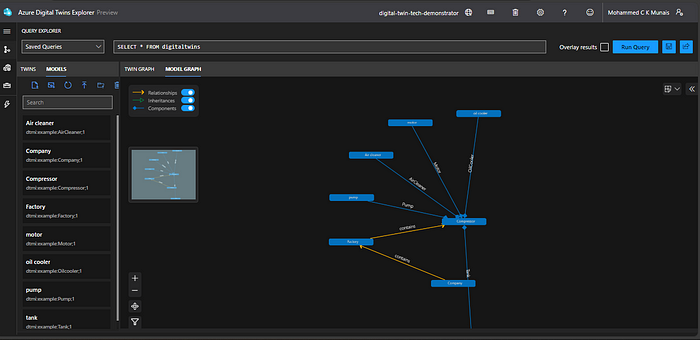

Digital twin model graph

This model graph is generated by uploading the DTDL JSON file. The files are mentioned below. We can upload all these files using Azure Digital Twin Explorer.

DTDL file for the component ‘compressor’

DTDL file for the component ‘air cleaner’

DTDL file for the component ‘motor’

DTDL file for the component ‘oilCooler’

DTDL file for the component ‘pump’

DTDL file for the component ‘pump’

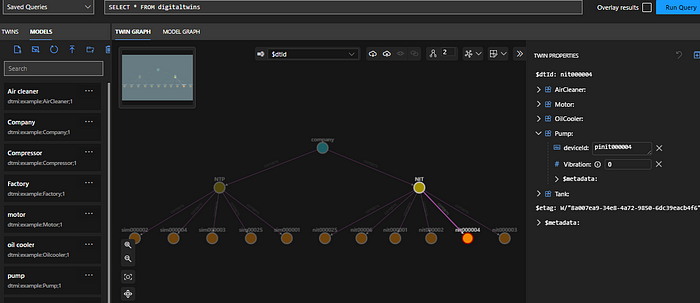

After uploading the model, we needed to create a digital twin using the model. This could be done through the UI, API, or a sample client app. I used a client app for the creation of the digital twin and establishment of relationships.

Figure shows twin graph after running client app.

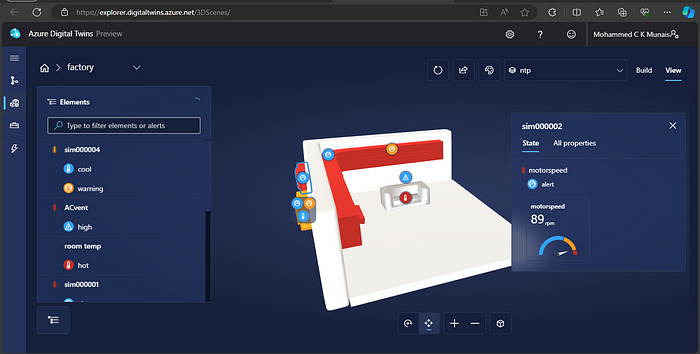

Initialize your 3D Scenes Studio environment

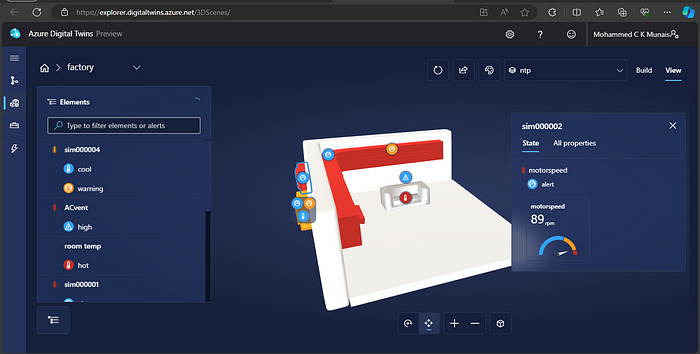

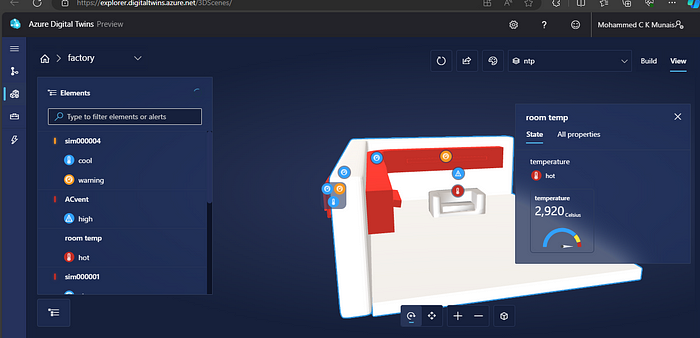

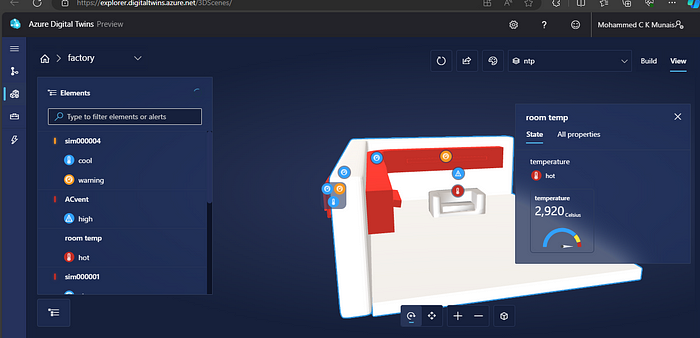

Final 3d view

Azure Digital Twins 3D Scenes Studio (preview) offers an immersive 3D environment that allows business and front-line workers to explore and analyze operational data from their Azure Digital Twins solutions, providing valuable visual context. Here, we created a simple 3D scene using Blender and uploaded it in the glb format. Subsequently, our twin data was configured to exhibit specific behaviors.

With Azure Digital Twins 3D Scenes Studio, monitoring our physical environment becomes seamless. We can integrate CCTV surveillance into the scene and configure various behaviours easily identified by color changes. Setting up alerts is also possible through this platform. The scene is already connected to Azure Digital Twin, ensuring real-time data updates.

Conclusion

In this comprehensive guide, we’ve explored the transformative capabilities of Azure Digital Twins, Microsoft’s groundbreaking platform that serves as the bridge between the physical and digital realms. By creating digital twins of physical assets and integrating real-time data from IoT Hub, businesses can unlock a new era of insights, analytics, and operational efficiency.

In the future blog posts, we’ll delve deep into connecting Azure Digital Twins with Azure Functions and Azure IoT, exploring additional functionalities and advanced features. Stay tuned as we continue to navigate the ever-evolving landscape of digital twins and IoT technologies.