A leading manufacturer of Flow Meters reduces operational costs with NeST Digital’s extended IoT feature.

A leading manufacturer of Flow Meters reduces operational costs with NeST Digital’s extended IoT feature.

Business Overview

NeST Digital provided an extended IoT feature to a leading manufacturer of electromagnetic flow meters, water quality sensors, and irrigation controllers in Australia and New Zealand. The customer faced challenges due to their dependence on a monopolistic source for supply and engineering, resulting in high operational costs. The customer also struggled with managing field operations and engineering support costs across multiple deployment sites.

Challenge

- Reduce dependency on a monopolistic source for supply and engineering, enabling the customer to achieve greater flexibility and cost savings.

- Reduce field operation costs at deployment sites, allowing the customer to improve efficiency and profitability.

- Reduce engineering support costs across multiple deployment sites, leading to increased productivity and cost savings.

Solution

NeST Digital analyzed the existing product and provided an extended IoT feature to tackle the customer’s challenges.

The solution methodology included the following:

- Developing a low-power operation electromagnetic flow meter and wireless communications module to transfer remote field data through a cloud network.

- Enhancing the onboard storage to reduce field data collection intervals.

- Enhancing the file system on the existing controller to support high-capacity storage.

- Simplifying field diagnostics and configurability to support customer-specific parameters.

- Providing a field utility for use by field technicians.

- Providing a Windows-based easy-to-use configuration and ensuring secure role-based access.

- Implementing low-power operation (Solar).

- Providing diagnostic data and alarms.

- Enabling user-configurable data logging and on/off times.

Value Delivered

NeST Digital’s solution and extended support helped:

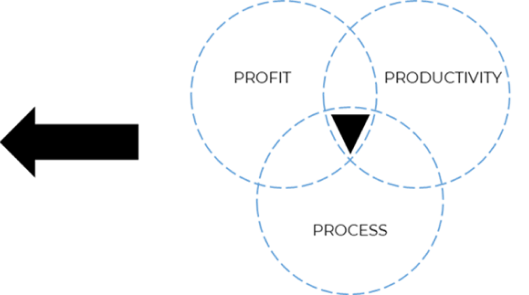

- Nullify dependency on monopolistic sources for supply and engineering.

- Reduce field operation costs by 15% at deployment sites, improving efficiency and profitability.

- Reduce engineering support costs across multiple deployment sites by 20%, increasing productivity and cost savings.

- Significantly reduce field data collection intervals using the onboard storage enhancements, enabling the customer to make faster and more informed decisions.

- Achieve a notable reduction in energy costs with low-power operations leveraging solar power.

- Improve the overall device performance and reliability by implementing diagnostic data and alarms, user-configurable data logging, and user-configurable on/off times.

SHARE