Explore the Powerful Synergy of Digital Twin and IoT in Our Latest Tech Demonstrator.

Explore the Powerful Synergy of Digital Twin and IoT in Our Latest Tech Demonstrator.

Business Overview

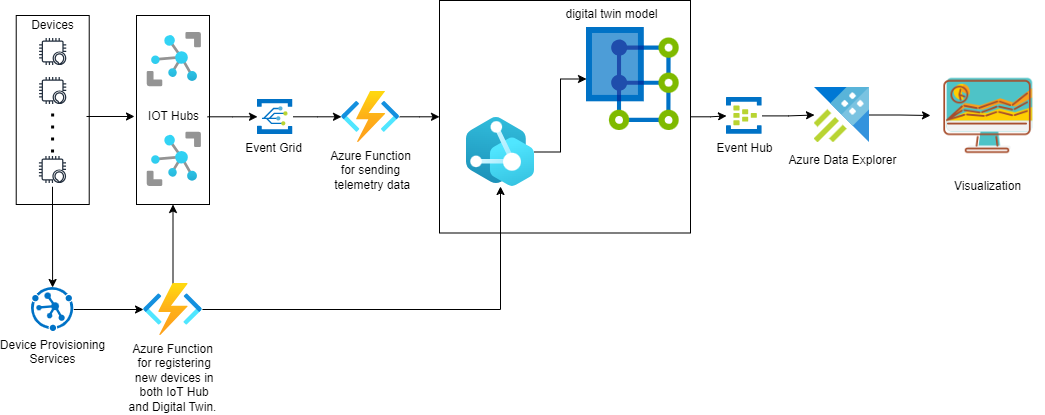

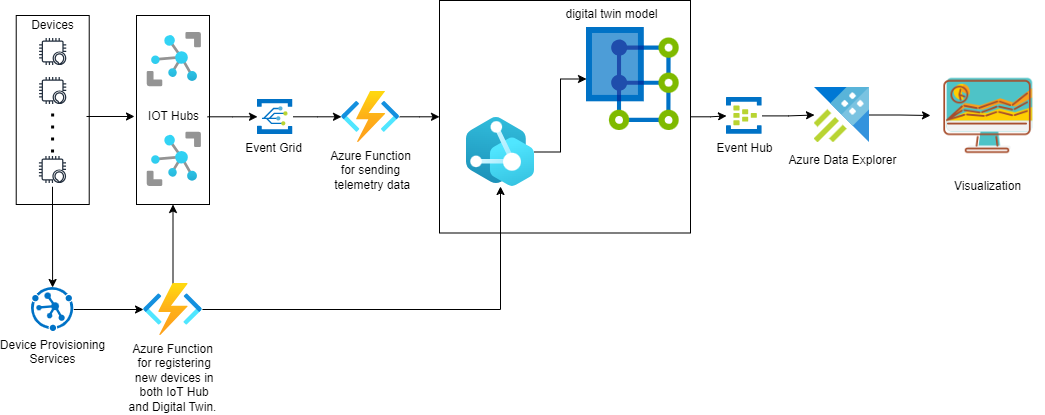

Let’s take you through our latest tech demonstrator, where we showcase NeST Digital’s expertise in seamlessly integrating IoT and Digital Twin technologies. This meticulously designed solution is crafted to revolutionize and optimize our clients’ intricate operations. Our comprehensive solution not only enhances operational efficiency but also guarantees significant cost reductions. This cutting-edge integration facilitates strategic decision-making on a grand scale, especially in the widespread deployment of devices. Moreover, it exemplifies its diverse applicability across varied industries.

Challenge

Despite their efficiency, modern compressors lack predictive maintenance capabilities, leading to unexpected downtime. Real-time monitoring challenges hinder optimization, while user difficulties arise from a complex array of settings.

Solution

We have created a Digital Twin tech demonstrator for compressors, creating a virtual replica for real-time monitoring, predictive maintenance, and user interactive learning. This enhances customer experience, extends device lifespan, and provides manufacturers with invaluable insights for continual improvement.

Key Features of the Solution:

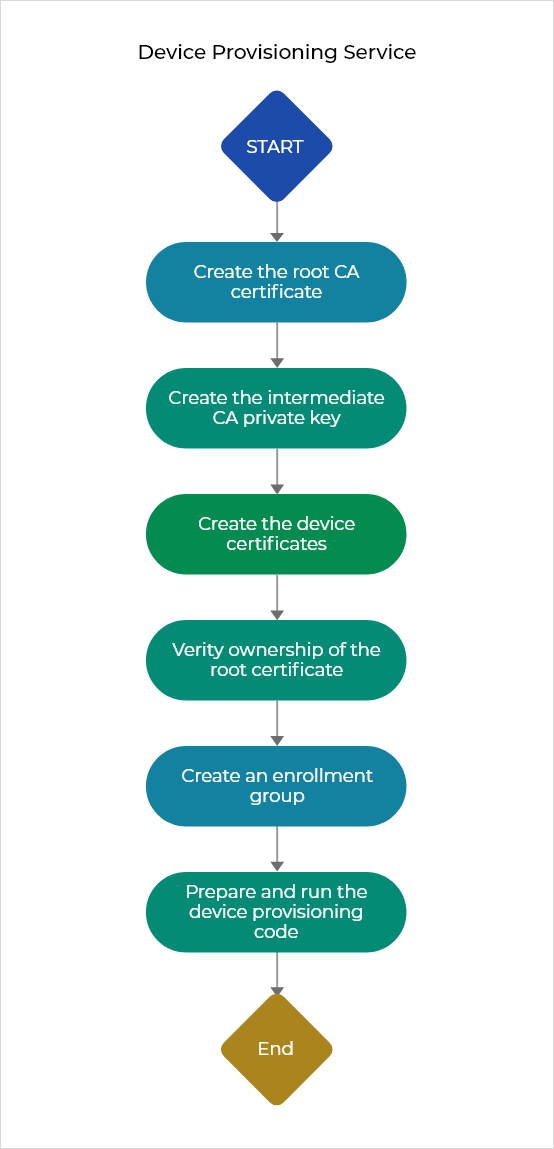

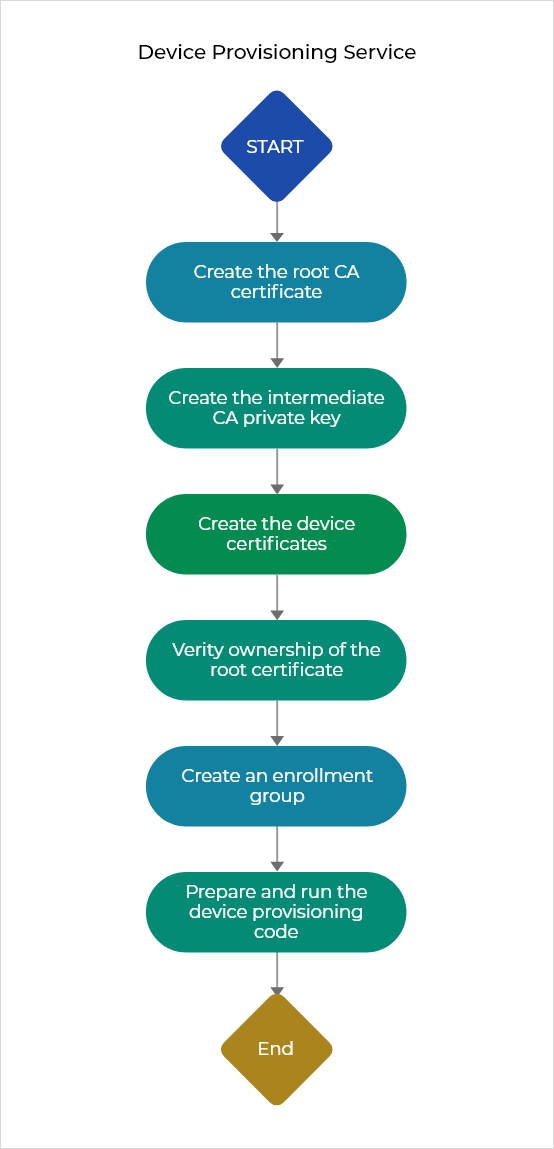

- Advanced Microsoft Azure cloud-based platform for IoT device control and real-time analytics.

- Azure Digital Twin for creating digital representations of real-world compressors.

- ADLS for historic data storage.

- Data ingestion and analysis to do preventive and predictive maintenance

Why Consider:

- Real-time Monitoring: Real-time monitoring and alerting based on various data points generated by devices

- Remote Operations: Ensure flexibility, responsiveness, and business continuity through remote monitoring and control.

- Remote management of devices without deploying field engineers to individual deployment sites

- Birds eye view of the entire deployment footprint and option to drill down on individual devices to monitor various parameters

- Predictive Maintenance: Anticipate and prevent equipment failures, minimizing downtime and extending asset lifespan.

- Cost Reduction: Optimize resource utilization, reduce operational costs, and enhance financial performance.

- Quality Assurance: Elevate product quality through real-time IoT monitoring and Digital Twin virtual simulations.

- Innovation and Adaptability: Stay ahead of industry trends and adapt quickly to market changes through IoT and Digital Twins insights.

- Agility in Dynamic Environments: Make real-time decisions and adjustments in dynamic business landscapes.

Value Delivered

Adopting NeST Digital’s IoT and Digital Twin solution can deliver significant value across various dimensions of manufacturing operations. It extends beyond technology implementation; it would reshape your manufacturing landscape, creating a dynamic, intelligent, and future-ready environment that drives long-term success.

SHARE