An IoT-based Data Monitoring System for Air Compressor

An IoT-based Data Monitoring System for Air Compressor

Business Overview

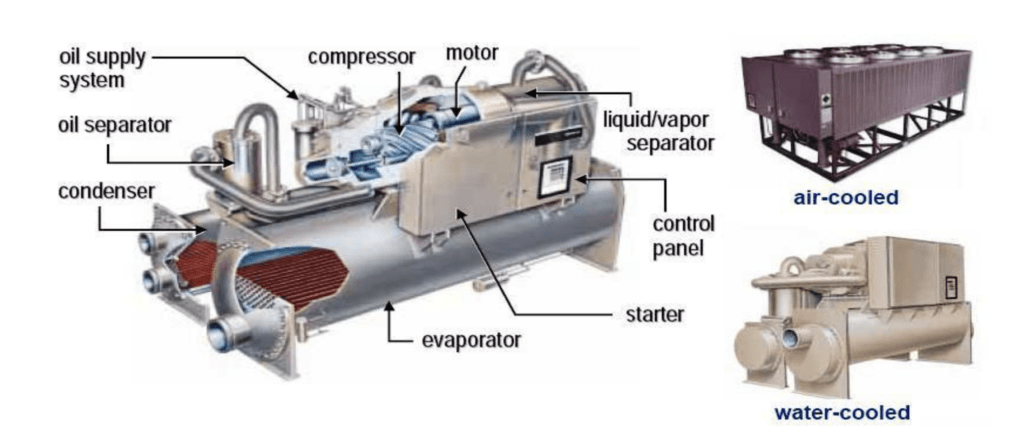

Preventive maintenance is crucial for an industrial air compressor to ensure the smooth functioning of the overall system and the associated machinery. To avoid unexpected downtime, it is essential to have a timely compressor maintenance solution that prevents unforeseen problems and operates to its full life expectancy.

With over US $120 M turnover and 400 products in production, our client was a leading air compressor manufacturer with a broad line of innovative and technologically superior compressed air systems.

Challenge

Due to several deployments in multiple geographies, the client could not achieve higher customer satisfaction through service management. Hence, the client wanted an IoT-based monitoring solution to arrive at a timely preventive maintenance schedule. Only with preventive maintenance could they ensure the machines worked hour by hour, day after day, by operating to their full life expectancy—without causing any unexpected downtime.

Solution

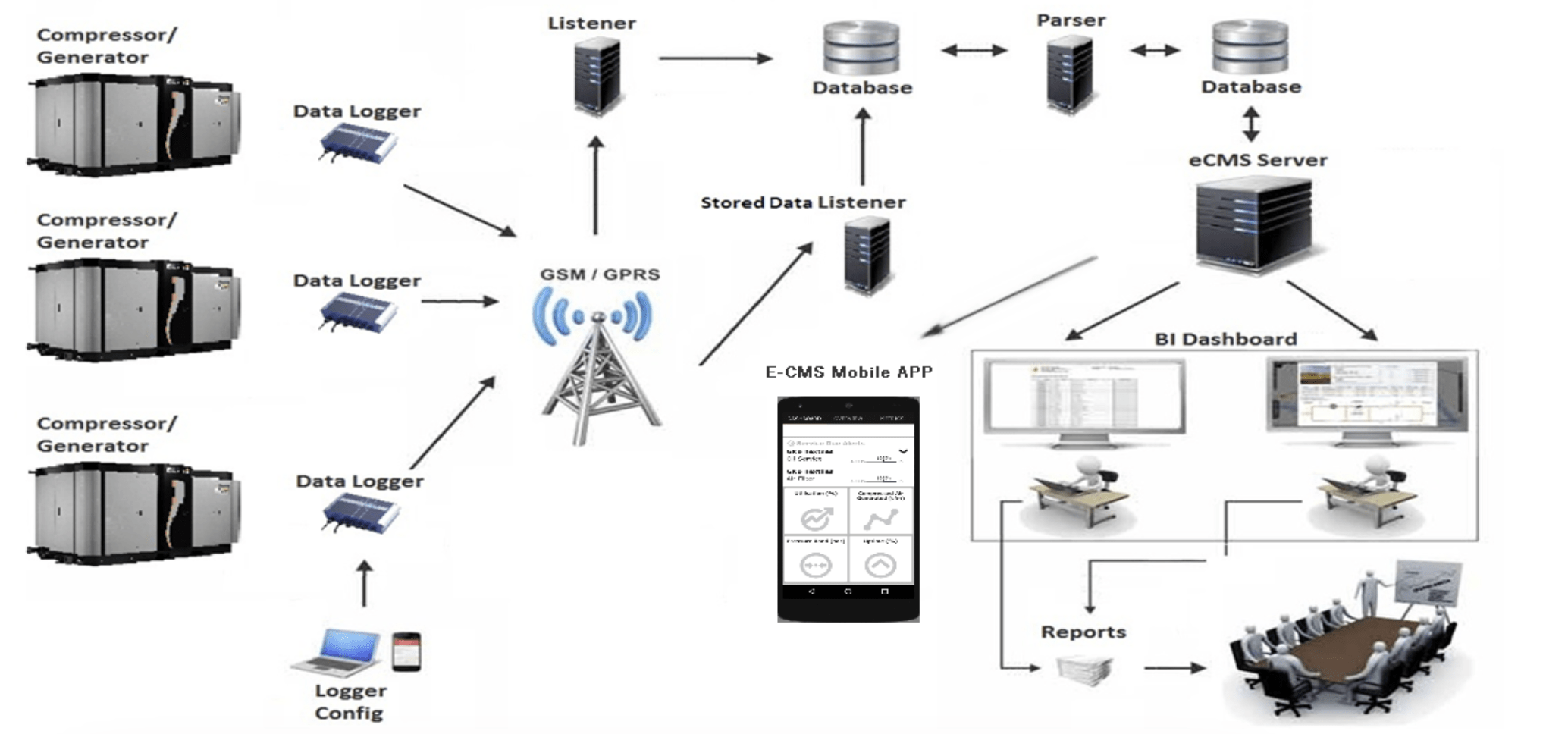

A state-of-the-art, highly customizable, and scalable SCADA (Supervisory Control And Data Acquisition) solution was designed using IoT to collect large volumes of data from compressors deployed across multiple geographies.

IoT made it easier for the client to send operational data to the cloud to receive data insights, which were then thoroughly analyzed to understand the various aspects of the equipment’s functioning. This also performed data cleansing to provide live, high-density MIS reports.

Features:

- Voice interface extension for EMR using Microsoft Azure NLP features, such as Language Understanding Intelligent Service (LUIS) and Cognitive Services

- An intelligent prescription mechanism that uses AI to generate prescriptions based on voice inputs from doctors and performs real-time medication-to-medication interaction checking using a blockchain-based prescription network

- Forward prescriptions to third-party integrations, including blockchain integration using Microsoft Azure cloud services

- Tenant management web interface that allows administrators to manage users, roles, and permissions for different branches or clinics

- Print/fax integration that enables doctors to print or fax prescriptions directly from their mobile devices or web browsers

Value Delivered

- Centralized monitoring: On-site monitoring and maintenance were reduced by monitoring the status of compressors installed across any geography globally.

- Higher customer satisfaction: Customer satisfaction level was increased by up to 25%, and the positive cost-benefit analysis was greatly appreciated. A well-performing compressor led to increased profitability and reduced risk of failures, along with minimizing costly repairs to a great extent.

- Scheduling preventive maintenance and proactive solutions: Scheduling regular checks of the components according to the client’s preference and proactive measures rectified issues seamlessly.

- High-intensity MIS reporting: Large volumes of data were collected from compressors deployed across geographies. Data cleansing was performed to provide live high-density MIS reports. Load tested against 50000 compressors data (217 parameters) concurrently with a turnaround time of < 4 seconds.

- Business analytics: Operational parameters were benchmarked with historical data, providing a solid base for business analytics. The data were analyzed further to improve the Mean Time to Repair (MTTR), first-time fix rate, downtime, and other parameters.

- Mobile app for trend analysis: Regular insights were gained by analyzing real-time data and trend charts, accessible both on the web and on a customized mobile app, from anywhere, at any time.

SHARE